In a market where every micron of material and every minute of downtime impacts profitability, smart manufacturers are making the shift to Metallocene-based LLDPE (Linear Low-Density Polyethylene) — and the results are transformative.

But what makes Metallocene LLDPE so special? And why are more Indian brands quietly switching to it?

Let’s dive in.

What is Metallocene LLDPE?

Metallocene-based LLDPE (Linear Low-Density Polyethylene) is a high-performance polymer produced using advanced catalysts that give it a uniform molecular structure. This results in:

- Higher mechanical strength

- Excellent puncture resistance

- Better sealing properties

- Optical clarity

- Flexibility even at thinner gauges

It’s used extensively in flexible packaging, stretch films, agri-films, and industrial liners — and is now gaining major traction in India.

How Metallocene LLDPE Drives Real Cost Savings

1. Material Down-Gauging – Metallocene LLDPE allows you to reduce film thickness by 10–20% without sacrificing durability. Example: A conventional 50-micron film can often be replaced by a 42–45 micron Metallocene LLDPE film — directly saving raw material costs.

2. Higher Machine Productivity – Better melt strength and bubble stability lead to higher extrusion speeds, fewer line breaks, and lower wastage.

3. Enhanced Product Performance – Films show superior toughness and sealing properties, resulting in fewer failures during transportation or usage, and fewer customer complaints.

4. Lower Total Cost of Ownership – When you add up raw material savings, faster throughput, reduced scrap, and fewer product returns — the cumulative impact is significant.

Real Industry’s Applications

Several leading Indian companies are already adopting Metallocene LLDPE to upgrade their packaging performance:

- Flexible Packaging Films: UFLEX Group and Cosmo Films leverage Metallocene LLDPE for high-strength, down-gauged lamination and barrier films.

- Industrial Stretch Wraps & Liners: EPACK Petrochem Solutions and Pyramid Technoplast produce stretch films and liners with enhanced load retention and toughness.

- Agricultural Films: Plastene India integrates Metallocene LLDPE for mulch films and greenhouse covers with superior mechanical properties.

- FIBC Liners & Bulk Packaging: Flexituff Ventures utilizes mLLDPE for creating impact-resistant liners and technical fabrics.

- Food, Beverage, and Personal Care Packaging: Manjushree Technopack Limited (MTL) and EPL Limited are using advanced mLLDPE blends for flexible laminates and high-barrier tubes.Several Indian companies are already integrating Metallocene LLDPE into their operations.

Global Validation

“Metallocene polyethylene resins provide unmatched film performance, opening up opportunities for thinner, stronger, and more sustainable packaging.”

(Source: Univation Press Release)

— Univation Technologies, Global Leader in Metallocene Technology

Global polymer giants like Dow, ExxonMobil, and Univation continue to invest heavily in metallocene technologies.

India is now catching up — and rapidly.

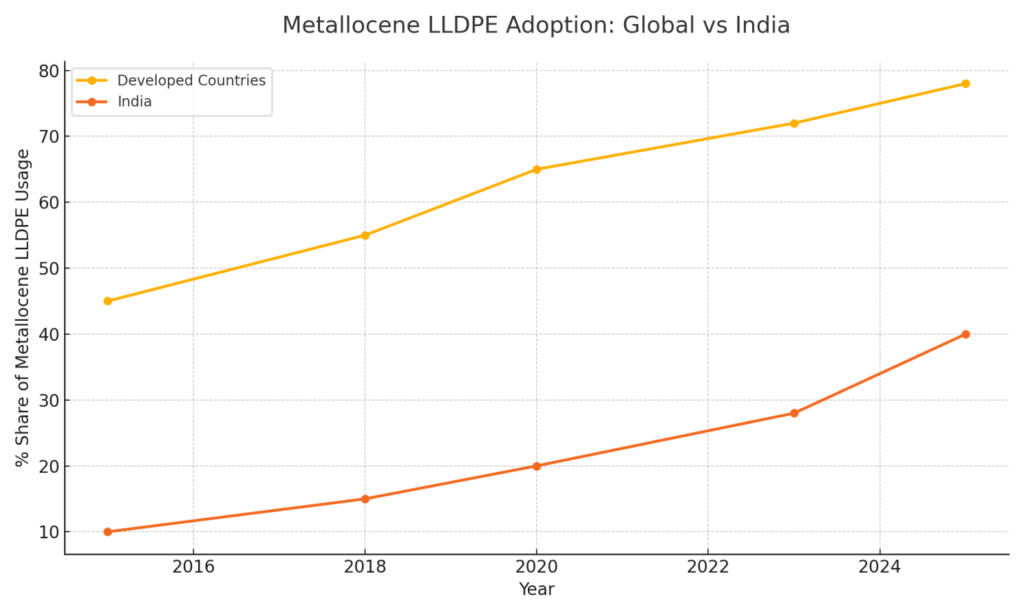

India’s Growth Story in mLLDPE

India’s flexible packaging and technical film sectors are witnessing a sharp transformation toward high-performance polymers like Metallocene LLDPE.

According to industry forecasts, the India mLLDPE market is projected to grow at a CAGR of 6.15% until FY2030, driven by demand for stronger, thinner, and more recyclable materials (Source: Chemanalyst India mLLDPE Market Report).

As India aligns with global trends, Metallocene LLDPE is poised to become the backbone of next-generation packaging and industrial solutions.

- Developed markets (like USA, Europe, Japan) already adopted Metallocene rapidly post-2010 for packaging.

- India started serious movement only in the last 5–6 years, with growth accelerating now (especially post-2022 regulations and plastic optimization drive)

Why Switch to Metallocene LLDPE?

If you’re a packaging manufacturer in India, the reasons to adopt Metallocene LLDPE are practical and immediate:

1. Material Down-Gauging – Replace 50-micron films with 42–45 micron mLLDPE without compromising strength.

2. Higher Line Efficiency -Improved melt strength = fewer line breaks and higher throughput.

3. Better Packaging Performance – Stronger films, better seals, fewer product failures during transport.

4. Aligns with Sustainability Goals – Supports thinner, recyclable structures and helps reduce total plastic consumption.

Need Help Switching to Metallocene?

At Bhavya Polyfilms x Raghav Polymers, we supply customized Metallocene LLDPE grades designed for Indian extrusion lines, stretch wrap applications, flexible laminates, and agri-film use cases.

➡️ Contact us today to request a trial or technical data sheet.

Let’s help you reduce costs, improve strength, and upgrade to smarter packaging.

???? Related Reads:

- How BOPP & CPP Films Are Evolving in 2025

- Understanding India’s Plastic Ban and What It Means for Converters

- Stretch Film Optimization: Why Thickness Isn’t Everything

✍️ Final Thought:

Metallocene LLDPE is more than a resin — it’s a competitive edge for Indian packaging companies ready to innovate.

Are you ready to make the shift?